The Cyclingskills newsletter

Are US patents and trademarks worth the money for small business?

In summary, while US patents and trademarks can provide some protection for American small businesses, they may not be the most effective tool when it comes to competing against Chinese companies. It may be more effective for US businesses to focus on creating unique products and building strong brands that resonate.

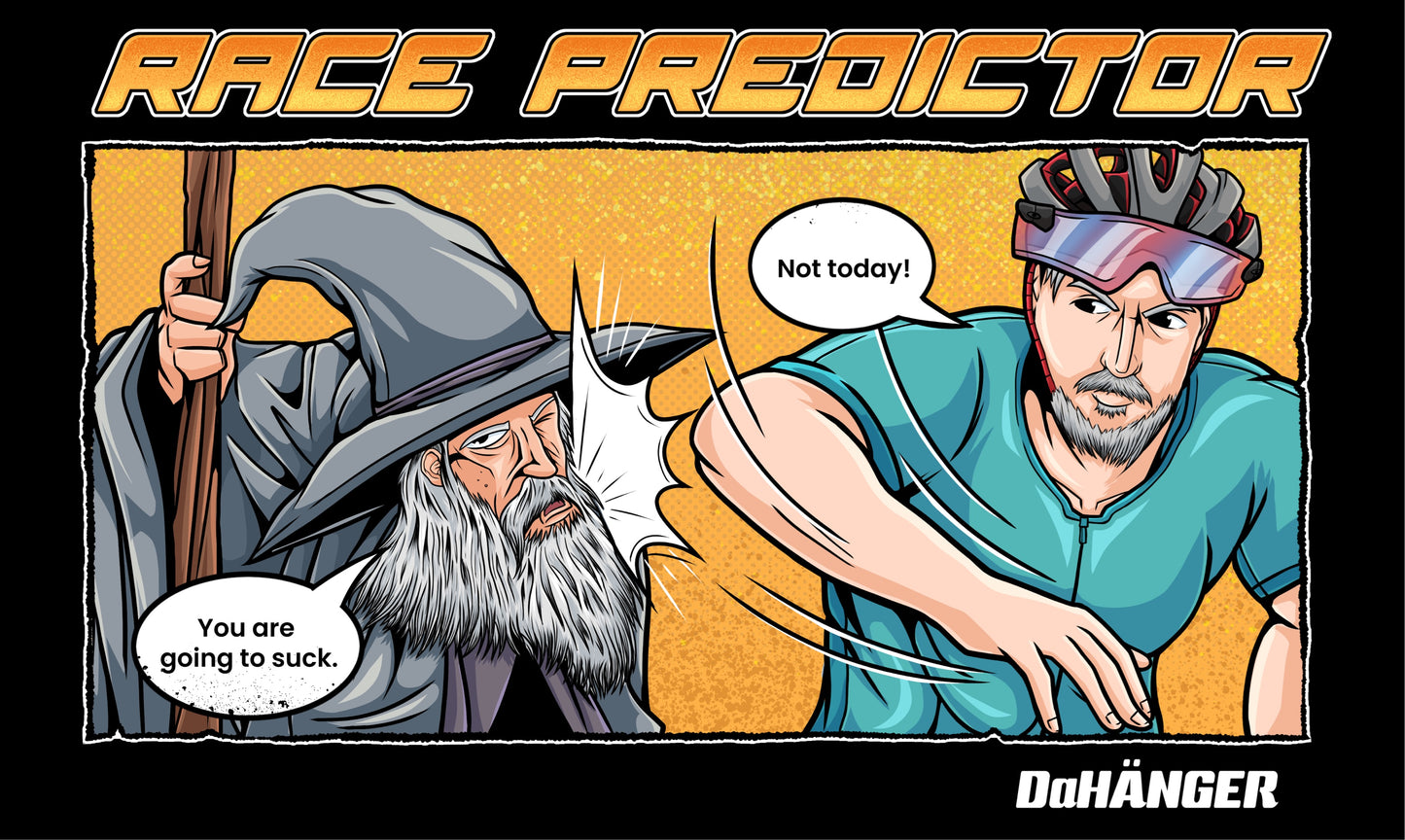

the most powerful Wizard in cycling

The other racers tried to ignore him and focus on their own training, but they couldn't help but wonder what Race Predictor knew that they didn't. Some of them even tried to bribe him or trick him into sharing his secrets, but he always remained elusive and mysterious.

How to ride berms on a Mountain Bike

learning how to ride berms on a mountain bike is a valuable skill that will make you a better, faster, and more confident rider. Whether you're a beginner or a seasoned pro, incorporating berms into your riding routine will help you improve your skills and have more fun on the trails.

Protecting Your Investment

This DIY project is easy to follow and requires minimal tools, so anyone can do it. Whether you're an avid cyclist or just looking for a unique way to display your bikes, this is the perfect solution. So, join us as we hang these two bikes in a 45-degree angle and make them look like they're riding into the sky on two LED strips.